Volkswagen Ignition System

Did you know that the electronics industry has had the fastest growth in the shortest amount time, compared to all other industries worldwide? But before I expound on that, let me just say that, the invention of numerous mechanical contraptions during the late 1800s, like James Watt's steam engine for example, started the transition towards new manufacturing processes which collectively gave rise to the industrial revolution. Much later Samuel Finley Breese Morse invented the single-wire electric telegraph system and developed the Morse Code. And sometime thereafter Alexander Graham Bell invented the first practical telephone system and their collective efforts, without discounting anyone else's efforts, changed telecommunications forever.Added to this, ancient records show that the first streets of Baghdad were paved with tar, and that the Babylonians used asphalt to construct the walls and towers of Babylon. Even The I Ching bears testimony to the fact that the cites of China used oil extracted in its raw state before refining was first discovered, during the first century BCE. By implication, tar, crude oil and pitch, were used as a sources of fuel for a very long time before paraffin was distilled from it. When this finally happened, the thin distilled paraffin was commonly used as fuel for lamps whereas the thicker residue was used to lubricate machinery. Soon after or in and around this time, when oil/fuel was extracted from coal, Étienne Lenoir successfully innovated the internal combustion engine followed by Nikolaus Otto who became famous for successfully developing the compressed charge internal combustion engine - the Otto engine.

Now Henry Ford on the other hand wasn't an inventor nor an innovator, by any stretch of the imagination, as many are led to believe. He was rather a business magnate and a captain of industry, who formed the Ford Motor Company, and sponsored the development of the "assembly line technique" for vehicle mass production. One could clearly say that their collectively efforts, without diminishing any other contributor's efforts by the very least, over a period of some 200 years, are partially responsible for the social changes and economic development that shaped societies that we live in today.

Electronics

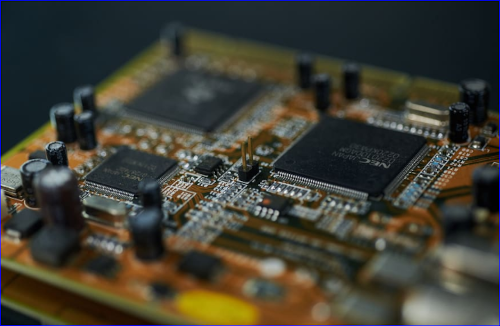

However, when the mechanical inventions of the Industrial revolution, is compared to modern day electronics, it stands out like a global coup. Initially there was the vacuum tube aka the electron tube, colloquially known as a valve. It gave way to semi-conductor devices as a whole. Transistors and gave rise to the analogue Integrated Circuits (IC) aka chip, followed by Transistor/Transistor logic TTL chips, followed by digital semiconductors like complimentary metal oxide semiconductors (CMOS) chips, ROM (digital read only memeory), RAM (random access memory) chips, EEPROM (electronically erasable programmable read only memory) chips.This was followed up by large scale integration (LSI) chips and Very Large Scale Integration Chips (VSLI ) chips. With the advent of multi-layer circuit boards and surface mounted technology, microcontroller (system on a chip) SoC and microprocessors (µP) became pervasive. Assembler language for chip families was developed and compiled to high level languages for programmable chips while software programming sat at the heart of most electronic devices and electronic systems. Communication protocols were developed and networks of various types became mainstream. All of this happened in 50 years as opposed to 200 years as mentioned above.

Volkswagen Ignition System

So you may ask, what has all this history to do with Volkswagen, Audi, Seat and Skoda and for that matter all vehicles from plains to trains? Well the short answer, everything! Much like the industrial revolution with its mechanical enginuity; cars and planes were also predominantly mechanical since its inception, its mechanical Ignition System was prone to imprecise ignition timing, resulting in improper fuel mixture burn, thus increasing its exhaust pollution. With the rise of telecommunications of old, so did the electric wires, and electrically controlled gauges, and relays switches in cars and planes multiply.The ever inflating cost of gasoline then triggered the invention of CDI (Capacitive Discharge Ignition Systems) which is in fact the first type of electronic contraption integrated into the Ignition System of a vehicle in order to, more precisely control its ignition timing making it more fuel efficient. These devices were available as add on kits and not produced as standard equipment in cars at the time. The preferred standard equipment was the IDI (Inductive Ignition System) and is the most common Ignition System found on all cars built prior to 1980. It used a coil, distributor incorporating breaker points in its Ignition System that was prone to ware-out due to arcing on contact.

During the 80's engines still used a coil and a distributor but was computer controlled, and by the 90's the computer evolved to an ECU, replacing the coil with a power pack. However, with the constant and ever increasing price of gasoline and looming environmental concerns about vehicle exhaust pollution; the automotive industry then accelerated its R & D into newer and denser, more fuel efficient engines and power-train systems capable of higher power output with enhanced robustness.

With the demand for higher-km/litre vehicles, Auto Ignition System needed to undergo an extreme revolution to produce a more advanced Ignition Systems. So, by the 90's an Insulated-Gate Bipolar Transistor (IGBT) was introduced into the Ignition System as a discrete component connected to the ECU. It essentially replaced the bi-polar transistor used in older systems.

Insulated-Gate Bipolar Transistor

An Insulated-Gate Bipolar Transistor (IGBT) is a fancy transistor, a semiconductor that functions like a switch. Unlike mechanical points, a semiconductor switch doesn't have moving contacts and is thus referred to as a solid state switch capable of handling Voltages between 600 Volts and 3300 Volts. So in a nutshell and IGBT is a fast solid state switch capable of switching speeds between 6 ns and 125 that and can be remotely controlled. It is thus controlled by the ECU via a driver module. The 12V DC traverses the coils winding and its negative side is connected to the collector of the IGBT which switches it to earth giving rise to induction in its secondary winding that produces the spark. Switching on and off also creates heat in the collector/ emmiter junction, cable of withstanding maximum junction temperatures of 150°C and 175°C. So as can be seen, an IGBT its just a fancy transistor, it is the latest technology needed for engines to operate at higher compression ratios that need higher spark plug voltage that can emit greater energy to ignite lean air and-fuel mixtures.Post Y2K technology

Starting from Y2K Ignition Systems were all ECU based, but the power packs of the 90's were replaced by dedicated coils per engine cylinder, yet making use of an Insulated-Gate Bipolar Transistor (IGBT) as discrete component but connected to the ECU. From 2004 to 2010 the discrete Insulated-Gate Bipolar Transistor (IGBT) integrated into individual Ignition Coils evolved to the all new Smart IGBT connected to the ECU. In later technologies the discrete / Smart IGBT evolve into a IGBT Module also integrated into each of the individual coils.What this implies, is that each spark plug have its very own coil completely independently switched by a Smart IGBT module driven by the ECU to an extremely tight tolerance. The ultimate objective is, that the ECU, whilst maintaining absolute stoichiometricity, triggers the Smart IGBT module that in turn fires the spark plug at the precise moment to attain absolute combustion.

The accurateness of the entire ignition timing process is determined by the ECU. Its internal programming tightly controls ignition timing process yet subject to inputs from several engine sensors as well as engine speed, torque and temperature. Should the spark occur too early, the resulting combustion chamber pressure, then applies force to the crankshaft before its force can be transformed into continued rotation. This could cause pre-ignition. Should the spark occur too late, the combustion chamber pressure peak weakens rapidly as the chamber volume rapidly increases as the piston moves downwards. This normally results in incomplete combustion, causing possible knocking. Both pre-ignition and knocking are totally undesirable and the most common cause of hydrocarbons - unburnt fuel exhaust white smoke. This unburnt fuel igniting in either the intake manifold or the exhaust system would result in back-firing.