Unlocking the Mysteries of Automotive Diagnostics

In the intricate world of modern automotive technology, the ability to

diagnose and troubleshoot issues has become an indispensable skill for both

mechanics and car enthusiasts. One of the key frameworks governing this

diagnostic landscape is the Onboard Diagnostics (OBD) system, specifically the

second iteration, OBD-II, which adheres to the standards set by the Society of

Automotive Engineers (SAE).

SAE and OBD-II Standards:

The SAE plays a crucial role in establishing standards that govern automotive

diagnostics. In the context of the VW Polo and many other vehicles, OBD-II is

the standardized system designed to monitor and report the performance of

various vehicle systems, ensuring compliance with emission regulations.

Stoichiometry and Emission Control:

Understanding stoichiometry is fundamental to comprehending OBD-II's role in

emission control. Stoichiometry refers to the chemically balanced ratio of air

to fuel necessary for complete combustion. OBD-II monitors this ratio through

sensors, with the Oxygen Sensor System (OXS) playing a pivotal role in

providing feedback to the engine control module (ECM).

EPC Light - Electronic Power Control:

One of the telltale indicators of an issue within the electronic realm of the

VW Polo is the Electronic Power Control (EPC) light. This warning light

illuminates when the system detects a fault affecting the engine's

performance. The EPC system is responsible for managing the throttle, ensuring

optimal power delivery and efficiency.

Check Engine Light and DTC Codes:

The infamous Check Engine Light (CEL) is another beacon of concern for

drivers. When illuminated, it signals potential issues with the engine or

emissions system. Diagnostic Trouble Codes (DTC), communicated through the

OBD-II system, provide mechanics with specific information about the nature of

the problem, allowing for a targeted and efficient diagnosis.

Limp Mode and Safety Features:

In the event of a critical issue, the VW Polo employs a safety feature known

as Limp Mode. This mode restricts the vehicle's performance to prevent further

damage, allowing the driver to reach a service center safely. Understanding

the triggers for Limp Mode requires decoding the specific DTCs stored in the

OBD-II system.

Sensors, Senders, and Actuators:

Central to the OBD-II system are an array of sensors and senders strategically

placed throughout the vehicle. These components, such as the Oxygen Sensor,

monitor various parameters and relay information to the ECM. Actuators,

controlled by the ECM, respond to these inputs by adjusting engine functions

to maintain optimal performance and emissions.

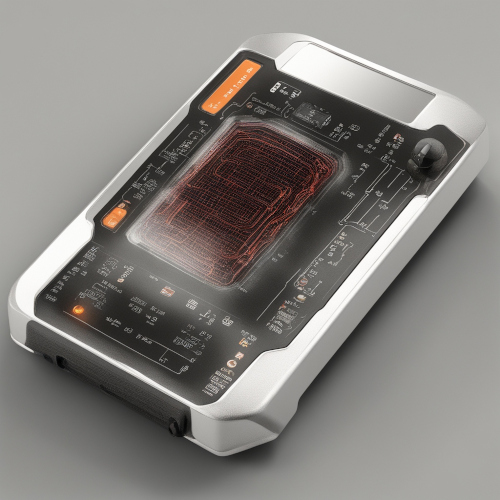

16-Pin OBD-II Connector:

Mechanics rely on the 16-pin OBD-II connector to interface with the vehicle's

diagnostic system. This standardized connector provides access to the wealth

of information stored within the OBD-II system, facilitating precise diagnosis

and troubleshooting.

Automotive Acronyms:

Navigating the world of automotive diagnostics often involves deciphering a

myriad of acronyms. From EPC to DTC,to HVAC, to OXS, to EGR and beyond,

mechanics adeptly use these shorthand terms to efficiently communicate

and clients and pinpoint issues with precision.However, it can confuse the

hell out of them.

Delving into the realm of automotive diagnostics for the VW Polo unveils a

sophisticated interplay of technologies governed by SAE standards and OBD-II

protocols. Mastery of these systems empowers mechanics to unravel

complexities, ensuring optimal performance and emission control for vehicles

on the road.

As technology continues to advance, a deep understanding of automotive

acronyms and diagnostic intricacies remains paramount for those entrusted with

keeping our vehicles running smoothly. However, it would be feasible even

advisable for vehicle owners to get get up to speed with Automotive

technology. Technology is here to stay and no matter how hard we try, cannot

will it away.