What your Electronic Power Control (EPC) Warning Light really means

Computers are ubiquitous or rather microcomputers, microprocessors and their peripheral systems and chipsets are. As such, they can be found in most electronic devices, ranging from laptops to printers, routers, radios, walkie-talkies, cell-phones and toys to mention but a few. In fact, microprocessors are so common place that they've taken over most hand held and personal electronic devices so-much-so that they are even embedded in our entertainment equipment, our cars, motorcycles, aeroplanes, ships and trains. It can thus be said that electronics in all its technological forms, have completely changed how we live our lives. These systems along with its sensors, sendors and actuators are referred to as On-Board Diagnostics (OBD) and since it's in its second revision, known as OBD-II or just OBDII.

Furthermore these On-board diagnostic (OBDII) digital computers interfaced with its dependency modules, electro-mechanical systems and sensors built into our cars have collectively taken-over and superseded most mechanical linkage functions, that were previously and traditionally used for acceleration, steering control and parking brake among several other. So, welcome to the world of drive-by-wire, (electronic throttle control) steer-by-wire, shift-by-wire, brake-by-wire and fly-by-wire which is currently widely used in aviation.

What your Electronic Power Control (EPC) Warning Light really says!

Your car's EPC light essentially indicates that there is an issue with the torque system of your vehicle. This torque system is your car's acceleration and braking system that now operates via drive-by-wire, shift-by-wire and brake-by-wire. In a nutshell, it's a computer chip supervised electronic system (ECU) that replaced the cable linkage previously situated between the carburetor and the accelerator pedal with an electrical/electronic interface.

This amber EPC light is an advisory light rather than a warning light -since warning lights are red in colour- is illuminated when the ECU detects a glitch in the torque system. When a glitch is detected, in most cases the ECU will enable 'limp home mode'. Limp mode is a fail-safe software-embedded, security and safety feature that inhibits the system, activates a rev limiter, shuts off boost partially or completely, resulting in a maximum 2500 RPM.

Thereby leaving only sufficient power to safely drive the car home in some cases. In other cases it could prevent the car from even starting. Limp mode also acts as a safe-guard against further engine / transmission trouble or possible runaway. Switching off the engine and disconnecting the battery may in some cases momentarily cure limp mode, but then again it may not due to the ECU's non-volatile memory. However as an advisory light, it begs for an OBD-II diagnostic scan, so that the Trouble Code (DTC) error may be diagnosed and repaired. This is best done sooner rather than later, as Limp mode sometimes manages to cures itself, yet bound to repeat itself continually until repaired. The ECU has a counter / timer monitoring how many times the same DTC was detected since the last start-up. If just a few times (considered negligible / mistakenly triggered) the counter resets itself and starts to recount from when it happens again.

Having said that, EPC lights and drive-by-wire systems aren't exclusive to "VAG cars" like most mechanics would have you to believe. The EPC light is a mandatory part of the OBD-II system hence fitted as standard equipment on "all post '96 cars". OBD regulations are written into Government legislation globally so that in time, the Department of Transport (DoT) may require all vehicles to regularly go for mandatory carbon emission tests in order the achieve road roadworthiness. They will access your cars under dash 16 pin obd connector to check its "Readiness Status". Readiness is an 2 x 4 digit binary number (hexadecimal) that look something like 1011 0110 or 1110 0101 or 0000 0000 or any combination of zeros and ones which is subject to the workings of equipment fitted in your vehicle.

Anyway, if you don't know, VAG stands for Volkswagen AG. The AG is an abbreviation for Aktiengesellschaft - implying incorporated. Aktiengesellschaft is the German term for a Public Limited Company (PLC). Thus the VAG group is comprised of ten car brands viz, Volkswagen, VW Commercial vehicles, Volkswagen Marine, Audi, SEAT, CUPRA, ŠKODA, Lamborghini, Porsche, Bentley and Ducati, spanning across five European countries. In a nutshell most if not all these vehicles have a EPC light and torque control circuit operated via drive-by-wire as standard equipment. But as mentioned previously, an EPC lights with drive-by-wire and brake-by-wire is not exclusive to VAG cars.

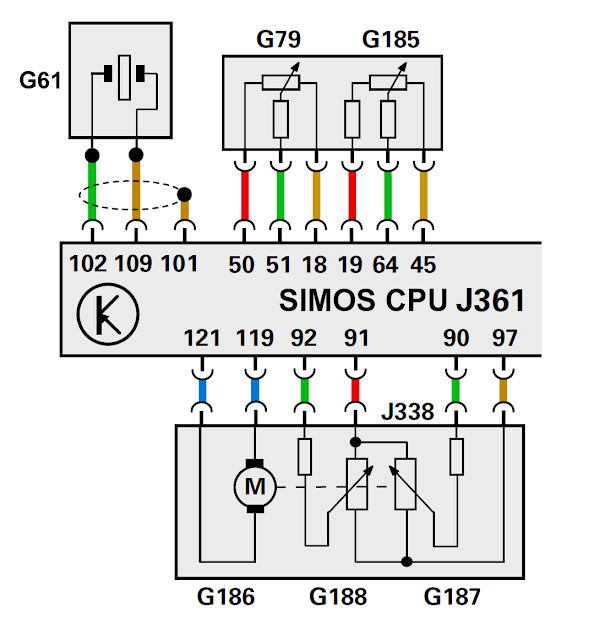

This torque circuit (throttle-by-wire) is a collection of interconnected electronic components amongst which are the car's battery, ignition switch, throttle body position sensor / potentiometer and throttle body actuator / stepper motor. The ECU itself, the braking system sensors and the wiring harnesses that supplies voltage / earth and feedback to and from the accelerator position sensor/ potentiometer and the throttle body motor, the cruise control switch, the instrument cluster and even one of the brake globes itself.

Possible problems

So by implication, with so many points of failure, so much can go wrong, For example, a loose battery terminal could cause the accelerator potentiometer input voltage to momentarily disappear for a fraction of a second, thus detected by the ECU which would then trigger limp mode. It could also be caused by a speck of dust has settled on the potentiometer slider that creates a brief intermittent contact. The ECU will however detect this and implement limp mode.

Then there is the dozens of wiring harnesses with their hundreds of connections. Several of them instrumental in the automotive torque circuit. Since electronics has taken over our cars, some having more than 3 dozen individual harnesses, collectively comprising of more than 3000 wires and a third as many connectors. It gives you an idea of multitude of electrical problems that can occur.

Male and female wiring harness connectors used in the automotive industry are fairly reliable however due to the under-bonnet conditions like extreme engine heat and morning freezing temperatures, humidity, steam, condensation, oil splatter, dust and vibration, can collectively give rise to corrosion inside wired plugs and sockets. Corrosion normally causes high resistive electrical conditions which upsets the functionality of the circuit concerned.

This could cause a myriad of problems in a myriad of circuits among which could be the MAF circuit, causing poor driveability and sudden jerking motions during acceleration flanked by untimed detonations. It could be the MAP circuit causing poor fuel economy and difficult starting and rough idling. Catalytic converter wiring would cause dark exhaust smoke that smell like rotten eggs due to the excess sulphur and the engine performance will be sluggish..... etc. Wait for the follow-up!