HIGH SPEED COMPUTERS

All modern-day motor vehicles using our roads today; and those manufactured since 1996 can literally be referred to as COW ("computers on wheels"). Since your car is less than 25 years in age, it certainly has a computer on board, but the level of control it has over your car is determined by its recentness. So the more recent your car the more control the computer has over its functionality.

BLACK BOXES

However, the computer in question is unlike the ones with the LCD screen, keyboard and mouse that everyone is familiar with, yet very similar in its processing ability. One could say these computers are akin to the flight recorders fitted to aircraft which in avionics are commonly called "black-boxes". But unlike the traditional PC, automotive "black-boxes" are heavily regulated by standards and legislation regarding consumer safety.

ECU

Industry wide automotive "black-boxes" are commonly known as Electronic Control Units abbreviated ECUs and is the home of on-board diagnostics software, named OBD II. This on-board diagnostic system in essence is a combination of hardware and software running an intelligent system that incorporates various types of the sensors, each integrated into the vital areas of the vehicle that monitors its overall performance.The most common of which are the engine RPM sensor, the crankshaft and camshaft position sensors, the car's air and coolant temperature sensor, the oil level sensor, road speed sensor, the accelerator pedal and throttle control sensor which is also known as drive-by-wire. The software consists of over 100 million lines of code which pools and controls dozens of electronic control units (ECUs) via the CAN protocol and CAN bus thus able to manipulate everything from Engine Electronics to ABS braking system, to Steering Assist, to Infotainment System, to Heating/Air Conditioning, to Airbag, to Instrument Cluster, to Tire Pressure Monitoring, to Back-Up Camera among so many other.

SENSORS

As such, ECUs have revolutionized and souped-up modern motor vehicles, giving them added fuel efficiency, safety, pollution reduction, speed on demand, and an early diagnostic malfunction detection. Restated, the ECU contains a self-diagnosis system capable of detecting glitches and small mechanical and electrical issues long before they actually occur thus saving you thousands in tow-in charges and would be expensive repairs. It eliminates the need to cross the fingers when you start hearing peculiar noises coming from the engine or transmission and it could prevent you from getting stuck on the road.

DIAGNOSTIC TROUBLE CODES

Vehicle dependent, the OBD II system alerts the driver to any malfunction in real time by flagging errors by way of digital code, displayed on the dashboard. Decoding these errors timorously and taking the necessary action would certainly avert more serious troubles later. Errors on vehicles without LCD display can be viewed with a diagnostic scan tool when plugged into its 16-pin ODB II socket. These vehicles would then also have CEL (check engine light) / aka MIL (malfunction indicator lamp, an EPC light among its menagerie of symbol warning lights. DTC (diagnostic trouble codes) are essentially fault codes, presented as five-digit alphanumeric codes that identify a particular problem in one of four areas in the car, viz: P-Codes (Power train), U-Codes (Chassis), B-Codes (Body) and U-Codes (User Wiring Bus Network).

A few example of these codes are P0195 - Engine Oil Temperature Sensor, P0304 - Cylinder 4 Misfire Detected, B1000 - ECU Malfunction, B1713 - Mirror Switch R Down Input Stuck High, C0050 - Right Rear Wheel Speed Circuit Malfunction, C0611 - VIN Information Error, U0130 Lost Communication With Steering Effort Control Module and U0324 Software Incompatibility with HVAC Control Module. Without a scan tool plugged into the OBD II socket it’s impossible to extract the DTC from the ECU non-volatile memory, let alone fix these faults.

ODB II SOCKET

It would therefore be fair to say that the OBD II socket has become the most important and indispensable means of diagnosing automotive problems hence also fair to say that it has become the most used automotive receptacle since its inception. That being said, OBD II GPS tracker is now also the most convenient vehicle tracking device on the market via GSM which plugs into a splitter / adapter cable. Armed with a SIM card, the GPS GSM module can be tracked on a cell phone tracking app and the software would even allow its user to disable the car’s engine remotely via GSM /GPRS and OBD II in the event the vehicle is hijacked or stolen. Unlike GSM where the cost of a data call is related to the time spent on the network, a GPRS data session is dependent on the amount of data sent and received. So by implication GPRS is “always on always connected”.

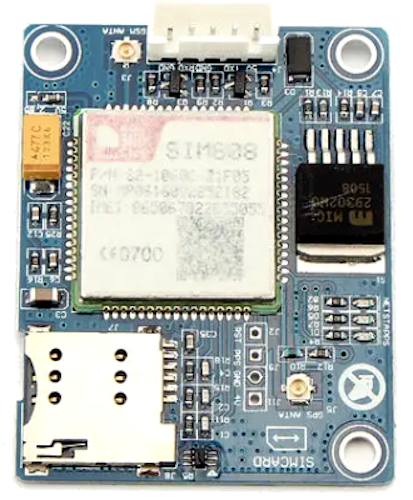

GPS MODULE

GPS modules generally have several convenient features amongst which is a real-time vehicle tracking system with a 180-day of tracking historical data accessible on a web server. GPS has time accuracy of 1 microsecond and an accuracy of less than 10 meters. It will continue working even if the cars battery is removed as it has a built-in 180mAh/ 3.7V battery. GSM module also has a host of security features but the best part of an OBD II GPS Tracker is that it's simple to install without any wire connections. It is purely a DIY matter of plug and play. A splitter cable that plugs into the cars original 16-pin OBD II port with two addition 16-pin OBD II ports, one for the GPS module and the other available to a scan tool.

SECURITY RISKS

All this fancy gadgetry doesn't come with risks. The first of which is the CAN protocol which suffers from several security issues that were originally ignored by most vehicles manufactures. Reason being that the various automotive networks and ECUs were initially designed to primarily gain physical access to the vehicle ECUs and speed / reaction-time was a secondary concern and more important that security which was then placed on the back burner. With a GSM SIM card in the GPS module that can directly communicate with the CAN bus and protocol it wouldn't be difficult for a hacker to gain access to the vehicle as it will be just another node on the internet. With remote interfaces like Wi-Fi, Bluetooth, or cellular that is accessible from outside of the car, access can typically be gained, thus aftermarket OBD-II devices have the potential to introduce security risks to an automobile and compromise the safety of its passengers. Connecting directly to the vehicle in this manner could result in control over safety-critical functions as CAN, by design, offers no protection from hacker manipulation.

With none existent comms security, somehow cars of the future with a CAN-Bus at its basis doesn't look it has a future at all. It reminds of other technologies that we were forced to abandon with the arrival of the new. Case in point, Vinyl Records for CD recorders, DVD that superseded video tapes, MP3 players that superseded audio cassettes and audio CD's, Flash drives that superseded removable media, etc. Solid state drives that is superseding hard drives. Would we have to abandon our CAN based cars like we did our other techno bits in favour of a new automotive protocols with features that has support for Kerberos, SSH, IPSec, OSPF authentication, VPNs, SSL and TLS?