DOOR LOCK PROBLEM ON POLO 9N

For the past week or so, I've noticed some peculiarity with my VW Polo's left side front passenger door locking mechanism. To risk stating the obvious, my VW Polo is a right hand drive car. Its auto lock feature is enabled, so when I drive and reach about 15 kmph all the doors lock simultaneously and the sound made by the four solenoids are clearly audible when this happens. But then, the front passenger door immediately unlocks itself. Initially it was the sound of the solenoid in the left passenger door that alerted me to the fact that it locks then unlocks itself.

Physically, all four door buttons/knobs are retracted at 15 kmph, three stays down but the left front passenger door buttons/knobs pops back up again. After this happened a few times, I re-locked it by pressing the internal central locking button on the driver's door panel. The left passenger door responded to the central locking lock instruction by re-locking but then immediately unlocks itself again. It just doesn't seem to want to stay down.

Thinking that it was just an electronic glitch and that the door might still be locked, even if the button jumps up. So I stopped the car, rolled down the left passenger window, climbed over the console, stuck my hand outside and pulled on the door catch. Surprise, surprise the door opened. So I thought to myself, this isn't good, in fact it really sucks. It's a huge safety risk driving with an unlocked door, especially considering the amount of bag snatching and car hijacking that's been taking place of late.

Thieves and criminals hanging out at stop signs and at a traffic lights patiently await the opportunity of an unlocked door coming their way, so that they can jump into your vehicle and rob you. I know of a case when three villains jumped into a nurse's car and forced her at knife point to drive to an ATM, to withdraw her daily cash limit. They then held her hostage until after 12:00 the evening just so that they could get the balance of her money from her account which was less than her daily limit for the next day. Fortunately they didn't harm her, but her nerves were totally shattered. Anyway, what I discovered much late is that when the passenger door button/knob pops up and I can manually press it down, and it doesn't pop up thereafter and the door stays locked.

Anyway, this door button/knob popping-up started to irk me and it was getting flippen irritating, so one afternoon when I got home from work, I decided to tackle the problem. I switched off the engine, removed the key from the ignition, and all the doors unlocked simultaneously, which is absolutely normal. So I re-locked the car with the fob remote key and all the buttons stayed down as they should. When I depressed the fob remote key unlock-button twice in quick succession, and all the doors unlocked which is also perfectly normal. From this I deduced that the electronic circuit responsible for unlocking the passenger door must get its power via the ignition switch, since it only unlocks when driving at 15 kmph and not whiles it's stationary and therefore there has to be a dedicated switch in each door.

But before I start taking things apart I needed to make absolutely sure that the problem is in the left front passenger door. I once again used the fob remote key to lock all the doors to make sure that they stayed locked, which they did. When I unlocked the Polo with the fob remote key, only the driver's door unlocks which is perfectly normal. But within 3 seconds the left passenger door also unlocks, and that's not normal. So I realized the problem is specific to the left passenger door yet I needed to make absolutely sure.

Sitting in the drivers seat, I turned on the ignition and opened the drivers door and saw the red light, door-open icon in the dashboard instrument cluster turn on. I repeated this process on the front passenger and rear doors, as well as the boot lid, all of which activated the red door-open icon except the left front passenger door. The next test was observing the interior light. As I opened the driver's door to get in, the interior light turned on, so I waited for the light to automatically turn off. I then reopened the door and the light turned on as it should. I repeated this action on the other doors which also worked as they should, except the front passenger door that didn't register that it was opened because the interior light stayed off.

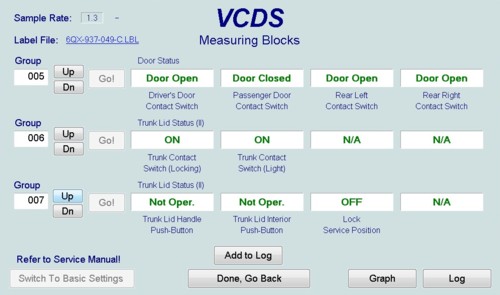

From this I deduced that both the instrument cluster door-open icon and the interior light is powered from the same switch in the door which is actually intermittent when not short circuit. Then I got out my laptop and my VCDS cable, rigged it up and Voila! With the all the doors wide open, as can be seen in the image below, the passenger door switch remained closed.

|

| As can be seen in the above image, with all four doors open, the software still sees the passenger door is closed |

Now that the preliminaries are out of the way, I can finally get out the screw drivers, spanners and the torx wrench and dismantle that pesky door mechanism. The following pics gives a fairly good idea of what it entails to remove the door lock; and on a scale of 1 to 10 with 10 being the most difficult I give it a 7. Removing and replacing the steel trace link that fits between the exterior handle and the lock is quite a challenge if you have large hands.

|

| The door panel before dismantling it |

|

| The plastic cover removed to expose the screws. |

|

| Removing door handle screw with hex key |

|

| The inside view of the door panel with the electric window plug unplugged |

|

| The slide mechanism mounting plate with all its screws removed |

|

| Removing the torx screws that secure the door lock |

|

| The sliding window removed from its clamps and stored safely |

|

| Screws of the backing pate, the inside door handle, the door lock and the inside door lever |

|

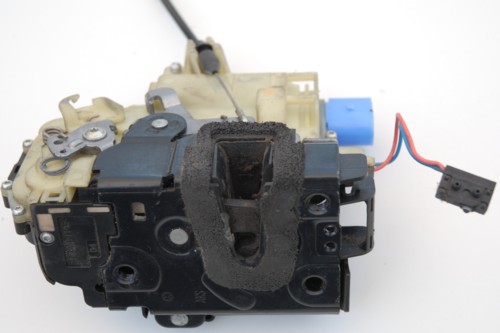

| The passenger door lock with the micro switch dangling on its blue and red wires |

I sprayed the the micro switch with some Q20 multipurpose lubricant and flicked it a number of times. I also cleaned the the metal pawl that activates the micro switch. It has a little notch in it, that fills up with grime. I suspect it is this grime and plastic burrs that cause the micro switch to misbehave. I used two straight pins to pierce the insulation of the micro switch wires in order to connect my Fluke multi-meter so that I could do a continuity tests.

|

| Continuity measurement of the micro switch in its normally open position |

|

| Continuity measurement with the micro switch depressed -closed position. |

|

| The steel trace link between the outside door handle and the lock. It is quite difficult to remove and put back especially if you have large hands. |

|

| The door lock "question mark looking" lever, is where the short steel trace cable links into |

|

| The steel trace must be held in the horizontal position before it can be inserted into place. |

|

| Showing the steel trace link in place, but it has to inserted during assembly when the lock in secured to the door frame. |

I know of a VW Pasat that had a similar issues. When the car is unlocked with the fob key neither of the inside nor the outside handles would open the door and since the door needs to be open to repair/ remove the lock, the car eventually had to go to the agents who charge a whopping R5500.00 to fix it. At least if the other doors had a keyhole to open them, it would have been so much easier. But it is all about cost saving for manufacturers.