AUTOSAR and the automotive black box.

Within the next few days the 11th AUTOSAR Open Conference will be hosted at the Portman Ritz-Carlton in Shanghai China. The date of this event is scheduled for the 6th - 7th November of 2018 and that's a mere 8 days from today. At this conference AUTOSAR experts from within the automotive industry will present their "Future Automotive System Architecture", both the Classic and the Adaptive Platforms. Both specifically developed to support high performance microprocessors, with improvements in the safety and security demands for autonomous driving vehicles, aka self driving vehicles. Essentially all motor vehicles of the future. |

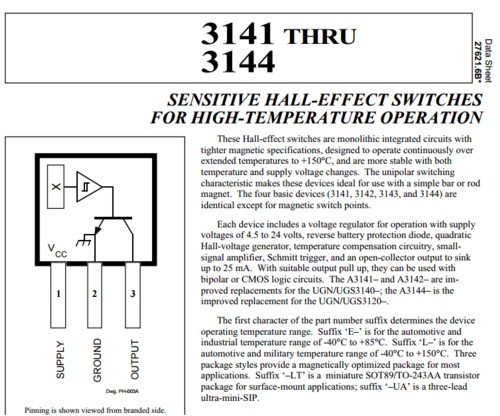

| AUTOSAR logo |

So what does all this mean in layman's terms. Well, it is AUTOSAR's attempt towards automotive standardization and for the development of smarter, safer and more secure vehicles in the future. So, who is AUTOSAR you may ask? The short answer; AUTOSAR stands for (AUTomotive Open System ARchitecture) and is a worldwide development partnership of over 250 vehicle manufacturers, suppliers, service providers and companies from the automotive electronics, semiconductor and software industry. Their collaboration and collective objective is to agree on a "Standardized Software Framework for Intelligent Mobility" and implement it, as the way forward.

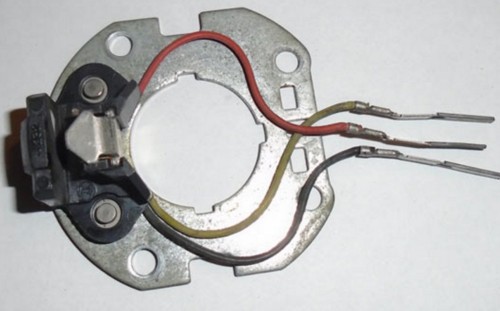

| An incomplete overview of the AUTOSAR Runtime Environment and how components plug into it |

Standardization is a good thing and when coupled to "open architecture" is even better. Case in point, Linux is open source and it revolutionized computing. Linux was selected for its ability to run on many and various makes and models hardware boards. Besides, Linux more-likely-than-not has the widest device driver support of any other operating system on the planet. As such, Linux became the de facto application software for developing specialized embedded devices in consumer electronics. For example, personal video recorders (PVRs), wireless access points (WAPs), personal digital assistants (PDAs), Global positioning systems (GPSs), in-vehicle infotainment (IVI), routers, switches, set-top boxes, navigation systems, home automation systems, car dashboard sytsems, security appliances, etc.

Linux is such a highly flexible platform that makes it relatively easy to port to other hardware architectures. As such Android relies heavily on its level of hardware abstraction (HAL). Android is an open source Linux-kernel-based operating system which revolutionized handsets far beyond phones, tablets and TV's. When Google acquired Android, they created the Compatibility Test Suite (CTS), which defined what OEM's handsets should comply with, to be Android-compatible. This CTS is just just a HAL (hardware abstraction layer) for the Android stack.

In the same vane AUTOSAR intends an open and standardized software architecture for automotive electronic control units (ECUs). It's RTE will act as a HAL sitting on a layer between the application software and the Hardware. It would form a standard ECU (black-box) usable by all manufactures with a layered software architecture that would reduce individual expenditures for research and development while mastering the growing complexity of automotive electronics.

The AUTOSAR operating system is also backward compatible with OSEK/VDX (ISO 17356) and consists of Basic Software Modules, Application program Interface (API), Specification of ECU Configuration Parameters (XML), Standardization Template, Generic Structure Template, Interoperability of AUTOSAR Tools. Hopefully the AUTomotive Open System ARchitecture would do for cars and safety in general what both Linux OS and Android OS have collectively done for consumer electronics as a whole.