That EPC light.

The most likely reason you're reading this blog post, is because you

encountered an EPC fault with your Volkswagen vehicle. I bet you wondered

what that yellow/orange light was when it lit-up or perhaps startled when

you car went into "limp mode". Whether you're driving a VW Polo or VW

Jetta, VW Golf, VW Caddy, VW Passat, T-Cross, Sharan, Touareg,

Transporter, or any other Volkswagen or even a German Audi, or a Czech Skoda

or a Spanish VW SEAT, you've come to the right place because they all have

an Electronic Power Control circuit.

In fact all "modern day" vehicles have EPC circuit, which loudly says

that the automotive industry have finally reached some consensus on

standardization. But let me tell you what the EPC light actually is. It's just

a signal light informing you that there is an error in your vehicles torque

circuit. That's the short answer, however, I can tell by the look on your face

that it wasn't a satisfactory answer, so let me give you the long

version.

The EPC light is part of the Electronic Power Control Circuit which is just

one of the components of OBD-II which was mandated by a certain regulatory

bodies with regulatory intent. Their initial intention was to limit carbon

emissions / exhaust fumes from cars on the street of America.

The California Air Resources Board (CARB) and the Environmental Protection

Agency (EPA) together with the Society of Automotive Engineers (SAE) and the

International Organization for Standardization (ISO) collectively originated

the On-Board Diagnostic (OBD) System because of high levels of smog produced

by automobiles throughout the USA.

Their initial On-Board Diagnostic System was subsequently superseded by the

all new and improved verion OBD-II, hence all cars manufactured post 1996 has

an Electronic Power Control Circuit and by extension an EPC light. The

European on-board diagnostics (EOBD) regulations are the European equivalent

of the American OBD-II.

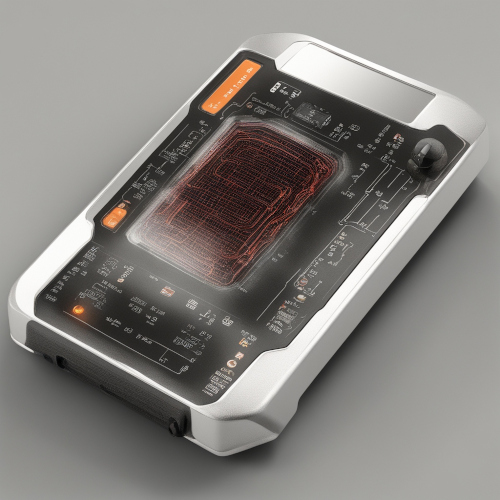

On-Board Diagnostic (OBD-II) is an automotive mechatronic, micro processor /

micro controller based computer system with programmed presets that

continuously monitors inputs from numerous sensors fitted through the

car.

It then computes/compares/ compensates these inputs against stored data and

drives various actuators to perform certain tasks. In a nutshell OBD-II is an

input/output (I/O) information processing system much like the PC / laptop /

or even your smart phone. By example, a keyboard, a mouse, a joystick, a

scanner and a microphone are common computer input devices whereas a HD

monitor, a printer, speakers and headphones are common computer output

devices.

Here the computer/laptop makes calculations based on its internal operating

system and software to do something intelligible for humans. However in

the case of OBD-II, its CPU (Central Processing Unit) is called an ECU

(Electronic Control Unit) and among its input sensors are the Accelerator

Position Sensor, Mass Air Flow sensor (MAF), Lambda O2 Sensor, Knock sensor,

Oli level sensor, Coolant Temperature Sensor, the Camshaft Position Sensor,

the Crank Position Sensor, the Wheel Speed Sensor etc, to mention but a

few.

Among its output actuators and solenoids are the drive-by-wire electronic

throttle actuator, the fuel injectors, the EPC light, Malfunction Indicator

Light (MIL), the Immobilizer, the Airbags and the Power Steering Pump, etc,

again to mention but a few,

This ECU is sometimes referred to as an Engine Control Unit especially when

intending to make reference to the TCU (Transmission Control Unit). The ECU is

sometimes even called ECM (Engine Control Module) when making reference to

other electronic control modules like the ABS module, the Instruments module,

the Central Electronics Module, the CAN gateway module, the Radio Module, etc,

again to mention but a few

However, the ECU and the TCU are collectively referred to as Powertrain

Control Module (PCM). The ECM essentially controls the efficiency of the

engine performance by using a Crankshaft Position Sensor to determine the

position of the cams in order to activate the injection of fuel into the

cylinders and the timing of the ignition spark to ignite it at precisely the

correct moment in petrol engines.

Likewise the ECM in Diesel engines, plays a huge role in the success of the

turbodiesel models. But in order for this to happen, an electronic throttle

control had to be introduced, replacing the cable from the pedal to the

carburetor system which was prone to idle speed deviation between a hot and

cold engine that became more and more prevalent as the components wore

out.

In so doing, the ECM can adjust the electronic throttle angle during

acceleration to achieve the right quantitative relationship ratio between the

actual airflow through the engine and the injected fuel thus maintaining

Stoichiometry. Controlling the throttle airflow on the fly, markedly improves

overall torque and driveability which is known as torque-mapping, an advantage

that is only possible with drive-by-wire.

So, the Electronic Power Control Circuit consists of the ECM, the Accelerator

Position Sensor, the Throttle Position Sensors, the Throttle Actuator, the MAF

/ Air Filter, the Fuel Injectors, the High Pressure Fuel Pump, Fuel

Temperature Sensor, Fuel Rail Pressure Sensor and Pressure Relief Valve.

The single accelerator position sensor is made up of two individual

potentiometers each acting independently of the other but collectively operate

with opposite polarity voltages supplied by the ECM, as a safety back-up for

one another.

Thus, if either potentiometer fails, the ECM will activate limp mode. This is

a safety measure that prevents the system from acting as if it had an

accelerator cable that got stuck in the runaway position and the makings of a

potential accident. The cruise control also has influence on the throttle body

and requires the brake pedal to be depressed to cancel the cruise

control.

The ECU normally takes this cancellation signal from the brake light MOSFET

low-side driver in the ECU. So either the brake pedal switch and the a brake

light bulb can cause an EPC error along with the aforementioned fuel supply

components. It's best to have a diagnostic tester to check for DTC errors via

the DLC connector. It would at the very least steer you in the right direction

to fix your EPC problem effectively.